Gyratory Compactors

EN 12697-10 | EN 12697-31 | AASHTO T312 | ASTM D6925 | AS 2891.2.2 | NZTA M10

|

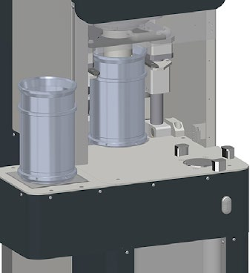

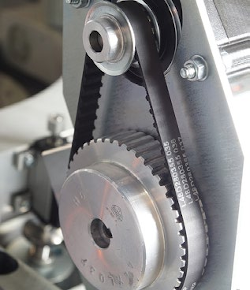

We highly recommend IPC Global's fully electro-mechanical gyratory compactors GALILEO and GALILEO Research, comprising of a robust precision-engineered steel structure incorporating the EmS Electromechanical servo-actuation mechanism for vertical load application and "Orbital" proprietary gyration and mould rotation system (Patent pending) delivering highly accurate and repeatable test results.

78-PV20G02: Galileo, fully Electromechanical gyratory compactor. 230 V, 50/60 Hz, 1 ph 78-PV20R02: Galileo Research, fully Electromechanical gyratory compactor, including integrated extruder, shear measurement, EmS motorized regulation of the gyratory angle and displayed on the control panel, PC software for data analysis. 230 V, 50/60 Hz, 1 ph Main features:

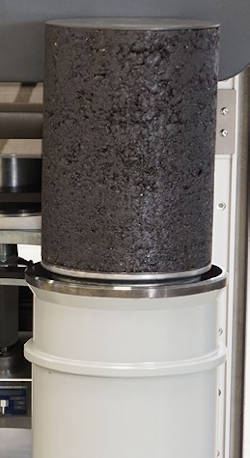

Operating principle: Standard specify the method for compaction of cylindrical specimens of bituminous mixtures using a gyratory compactor. Such compaction is achieved by combining a rotary shearing action with a vertical static force applied by a mechanical head. The method can be used for:

Standards apply to bituminous mixtures (made either in laboratory or from on-site sampling), with aggregates not larger than 37.5 mm. During operation the bituminous mixture is contained in a cylindrical mould (100 or 150 mm diameter). Compaction is achieved by the simultaneous application of a low-static compression and a shearing action, which results in the motion of the centre-line of the test piece, which generates a conical surface of revolution while the ends of the test piece remain approximately perpendicular to the axis of the conical surface. The gyratory compactor Galileo can be used as part of your Superpave performance based testing program. |

|

Internal angle measurement apparatus ILS

78-PV0255: ILS device for internal angle measurement for Gyratory compactors, conforming to EN 12697-31, annex C. Complete with Excel Macro and PC connection cable Main features:

The importance of a precise gyratory angle has been widely noted. The measurement of the internal angle represents, in practice, the most accurate method of calibration. This method comprises two individual values: angle between cylinder and top plate and angle between cylinder and bottom plate. The average of these two values is taken as the "internal angle". To date the internal angle calibration of gyratory compactors has been considered a difficult task leading to wide variations in results even between machines of the same brand. The ILS device can also be used on any other makes of gyratory compactors. |