Rock Sample Preparation Equipment

ASTM D4543 | EN 12390-1 | ISRM

|

Laboratory coring machine and bits is specifically used in the laboratory for cutting core samples from hard materials such as rock and concrete.

45-C0330: Laboratory coring machine, 2-speed, complete with water inlet. 230 V, 50-60 Hz, 1 ph Specs:

A clamp is provided to firmly secure the material during the cutting cycle. The coring area is protected by a transparent cylinder. A special clamping device to prepare rock samples from core pieces and drill bits available for purchase separately. 45-C0331: Clamping device for cores up to 100 mm dia., complete with transparent guard. 45-C0342: EX core drill bit 21.46 mm dia. 45-C0343: AX core drill bit 30.10 mm dia. 45-C0344: Core drill bit 38.1 mm dia. 45-C0345: BX core drill bit 42.04 mm dia. 45-C0346: NX core drill bit 54.74 mm dia. 45-C0347: Core drill bit, size HQ - 63.5 mm dia. 45-2017ABS00626: Core drill bit 50 mm dia. x 130 mm length |

|

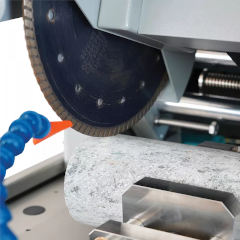

The laboratory Core Trimmer machine is used for the preparation of rock specimens for strength and deformation testing from block samples or from drill core obtained in the field.

32-D0528/A: Laboratory core trimmer, cut-off and grinding machine up to 75 mm diameter specimens. 230V, 50Hz, 1ph 32-D0528/A2: Diamond cutting blade. 230 mm dia. x 2,5 mm thickness 32-D0528/A3: Double-faced cup wheel 230 mm dia. x 16 mm thickness Main Features:

The laboratory Core trimmer machine allows you to prepare a rock core specimen according to the following procedure: 1. Specimen Cutting Core sample rock is clamped in the jig for holding and feeding during the cutting process. During the cutting phase, water is continuously recirculated for blade cooling and flush cuttings. The precise manual feeding system moves the blade horizontally. Once the specimen is cut, back off the blade and turn off the saw. Unclamp the specimen, reposition and repeat the procedure on the opposite side. 2. Grinding In order to reach the flatness and parallelism tolerances, a grinding phase is usually required. The rock core specimen is again clamped with the holding jig and is ground using the diamond impregnated grinding wheel mounted on the opposite side of the machine. The specimen ends are typically colored with a waterproof marker, prior to the start of grinding, in order to monitor where material is being removed. Grind each end one at a time. In this phase, the cooling water system is used to cool the specimen and grinding wheel. |

|

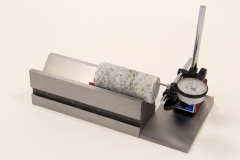

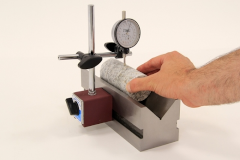

Rock sample verification apparatus is used to verify the dimensional and shape tolerances of rock core specimens up to 75 mm dia. by 120 mm length.

The straightness of the cylindrical surface can be easily verified as well as flatness and verticality of end surfaces by the same dial gauge using the magnetic holder in the desired position. 32-D0539/B: Rock sample verification apparatus to ASTM D4543 complete with: - "V" block with dimension 85 x 85 x 250 mm - 5x0.001 mm dial gauge with magnetic holder - additional platen 100x180x8 mm - 6 magnets for core locking 32-D0539/B1: Flat test surface 300x300 mm made in cast iron to be used with rock sample verification apparatus model 32-D0539/B |