Cutting and Coring Machines

|

CONTROLS Concrete, asphalt, rock and masonry universal saw, completed with the suitable accessory, can be used to cut concrete, asphalt and rock cores, and irregular rock samples in order to obtain geometrically defined samples.

It can be fit various 450 mm dia. blades. 55-C0210/D: Concrete, asphalt, rock and masonry saw. 380V, 50 Hz, 3 ph The head is adjustable in height. The tilting motor head permit cuts up to 45° inclination. The tank and the trolley are zinc plated to avoid corrosion. Complete with water pump for cooling the blade and double filtering system. Cutting blade, and accessories to cut cores, asphalt, rock and other building materials, not included. 45-C0211/5: Diamond blade, 450 mm dia., for hard rock 55-C0210/1: Diamond blade, 450 mm dia., for concrete 55-C0210/2: Diamond blade, 450 mm dia., for asphalt 55-C0210/5: V shaped support for cylinders and cores up to 160 mm dia. 45-C0210/6: Locking clamp device for irregular pieces |

|

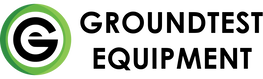

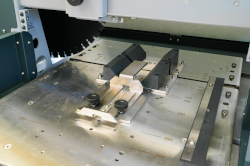

Universal asphalt and concrete saw, MULTISAW is a unique machine specifically designed by IPC Global for laboratory use to precisely cut Asphalt, Concrete and Rock samples.

77-PV47005: MULTISAW, asphalt saw, complete with multi-slab jig. Blade not included. 400V / 50 / 3ph An easy-to-use spacer system sets the specimen position and allows beams or cores to be cut without the need for measurement. The saw blade advances and retracts to the home position by a user-friendly hand wheel. The Multisaw includes the multislab jig, complete with table and manual clamping device for slabs. Cores at the desired length. It can be fitted with 650 mm dia. blade with a maximum cutting depth of 200 mm and prism length of 500 mm (extendable to 700 mm, on request). The Multisaw allows an easy-to-use sawing system for the Four-Point Bending Beam tests, Two Point Bending Beam tests, TSRST, Texas Overlay Test, Prall Test, Semi-Circular Bend Test, Wheel Tracking Tests with large and small devices, or any concrete beam or cylinder. The system allows cylindrical cores with diameters from 100 to 150 mm, and 200 mm dia. to be quickly and accurately cut to different lengths from 10 to 300 mm. 77-PV47000/1: Diamond blade 650 mm dia. for asphalt 77-PV47000 / C1: Diamond blade 650 mm dia. for concrete 77-PV47000/2: Sacrificial PVC tube for 100 mm dia. core (consumable) 77-PV47014: Manual core locking Jig for round cores, from 38 to 200 mm diam., to cut samples with manual feeding, from 10 to 300 mm length. 77-PV47020: Trapezoidal specimens jig to be used in Two Point Bending Test, according to EN 12697-24 and 26. 77-PV47025: Jig for Wheel Tracking cores according to AASHTO T324, Semi-Circular Bend test samples according to EN 12697-44 / AASHTO TP105 / AASHTO Draft (except the notch) and Disk Shaped Compact Tension samples according to ASTM D7313 (except the notch and two holes ). 76-PV47014 is also required. 77-PV47030: Jig for Texas Overlay Test according to TX-248-F. 77-PV47011 or PV47014 is required. |

|

Universal core drilling machine is ideal for field where it is necessary to core at any angle.

83-C0301/D: Heavy duty universal core drilling machine, three speeds motor. 230 V, 50-60 Hz, 1 ph The extension columns permit the holding at a maximum vertical or horizontal distance of 3850 mm. The rack feed (drilling excursion) is 1000 mm long. The core bits, strap wrench and extension columns, are not part of the machine and have to be ordered separately. The core bits we propose have fixed standard coupling assuring the best alignment, fast and easy fitting and disassembling. 83-C0300/1: Extension rod 228 mm long 83-C0300/2: Strap wrench for fitting and removal of core bits Coring bits and accessories Thin wall diamond bits with bronze welded sectors suitable either for concrete or asphalt. Fixed standard coupling assuring the best alignment, fast and easy fitting and disassembling. Bit length 400 mm approx. They can be used for either asphalt or concrete. The core extractor is offered as an optional accessory and simplifies the removal of the core sample from the hole. Core bits To take core Weight approx. Suitable core extractor dia. mm kg 83-C0320 50 2.2 83-C0310/2 83-C0321 75 2.8 83-C0311/2 83-C0322 100 3.7 83-C0312/2 83-C0323 150 5.4 83-C0313/2 83-C0324 200 7.5 83-C0314/2 |

|

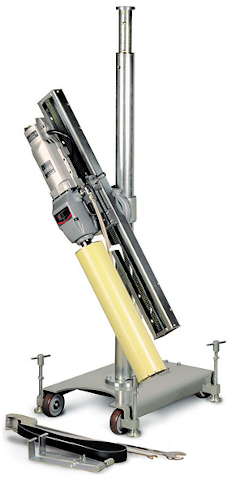

Portable core drilling machine

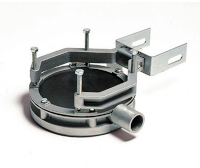

83-C0350: Universal portable core drilling machine, three speeds motor. 230 V, 50-60 Hz, 1 ph The machine is composed by three main parts:

These three parts can be easily assembled and disassembled for transportation. The support steel column can be angled with respect to the base. The motor support is mounted on rollers and ball bearings. The aluminium base can be easily fit on site by anchors, by suitable holding column or by vacuum using the appropriate accessory. The machine can be used at any angle within the horizontal position by the appropriate fixing making sure that flushing water does not drop directly onto the motor. For internal use we suggest the machine is fit with a water collector system. 83-C0350/1: Kit attachment for vacuum connection. Fits the opening in the middle of basement. Comprising the connection plate with gasket, the vacuum gauge and the base gasket. 83-C0365: Vacuum pump with reservoir. 230 V, 50-60 Hz, 1 ph 83-C0350/5: Water collecting ring for bits up to 150 mm dia. Confines waste water on the surface. It has to be connected with a suitable electric pump. 83-D2020: Portable water pressure tank, 10-15 l cap. Useful when tap water is not available. Core bits, extension, strap wrench, and other accessories available separately. (Same as above) |