Single, Double & Universal Wheel Trackers

EN 12697-22 | AASHTO T324

|

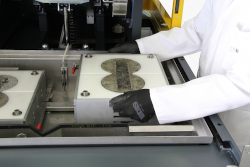

Dyna - Track Single Wheel Tracker from CONTROLS

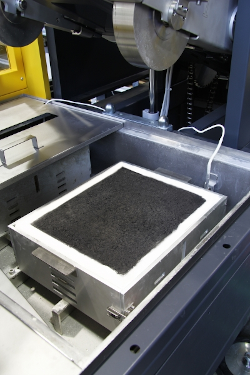

78-PV3502: DYNA-TRACK, Wheel tracking machine. 230 V, 50-60 Hz, 1 ph Main features:

The wheel tracking apparatus consists of a loaded wheel, which bears on a sample held on a moving table. The table reciprocates with simple harmonic motion through a distance of 230 ± 5 mm with a frequency of 53 passes (± 1%) per minute. For research purposes the test speed can be adjusted by inverter control. The wheel is fitted with a solid rubber tyre of outside diameter 200 mm. The wheel load under standard conditions is 700 ± 10 N. The wheel tracker is fitted with a temperature controlled cabinet with a temperature range from environment to 65°C ± 1.0°C. The sample may be either a 200 mm diameter core or a 300 x 400 mm slab of asphaltic mixture from 25mm to 100 mm thick. A 25 mm stroke LVDT transducer is included for monitoring rut depth in the centre of a sample during a test to better than 0.1 mm. The deformation and sample temperature is recorded by the internal data acquisition and control system, then sent to the Windows® compatible software. The Dyna - Track Single Wheel Tracker can be used as part of your Superpave performance based testing program. |

|

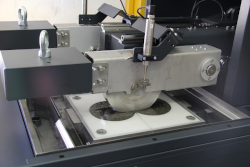

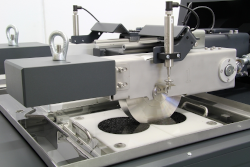

DWT Hamburg type Double Wheel Tracker from IPC Global

78-PV31A15: DWT double wheel tracker (Hamburg type). Conforming to AASHTO T324, in-water specimen conditioning. Complete with laptop PC and software. Set of moulds to be ordered separately. 380 V, 50 Hz, 3 ph 78-PV31A25: DWT double wheel tracker (Hamburg type). Conforming to AASHTO T324, in-water specimen conditioning. Complete with laptop PC and software and clear transparent sliding door. Set of moulds to be ordered separately. 380 V, 50 Hz, 3 ph Main features:

Machine body: Sheet steel, powder coated. Trasparent sliding door. Loaded wheel system: The wheel load is 705 N. The system includes a motorized lifting system for raising the wheel assembly at the end of the test. Wheel tracking carriage: The wheel is moved 230 mm backwards and forwards on the top of the slab, which is fixed. The speed is adjustable via the PC from 20 to 30 cycles per minute (40 to 60 passes). The longest slab dimension is oriented to the wheel's direction of travel. Special slab moulds for circular samples obtained from coring or gyratory compactors are also available. See accessories. Temperature control system: The AASHTO Hamburg type Standard states that the test must be performed in a water bath with a temperature range of 258 to 70° ±1°C. A water level of about 20 mm above the sample has to be maintained. Where a heated air environment is specified, the specimen, during testing, must be maintained at uniform and constant specified temperature ± 1°C. The DWT Double Wheel Trackers fully satisfy and exceed the above requirements: the temperature accuracy is ± 0.5°C. Impression measurement system: Each wheel is fitted with RUT DEPTH transducers for measuring deformations from 0 to 40 mm ±0.01 mm. The DWT Hamburger type Double Wheel Tracker can be used as part of your Superpave performance based testing program. |

|

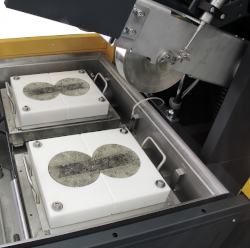

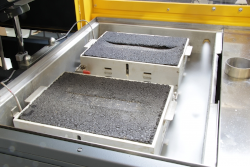

DWT Universal AASHTO/EN Double Wheel Tracker from IPC Global

78-PV33B05: DWT Wet and dry universal double wheel tracker Conforming to Hamburg type AASHTO T324 and EN 12697-22 Small Size Device, in-air and in-water conditioning. Complete with both stainless steel and rubber wheels, laptop PC, software and clear transparent sliding doors. Set of moulds to be ordered separately. 380 V, 50 Hz, 3 ph+N 78-PV33D05: DWT Wet and dry universal double wheel tracker Wheel load adjustable up to 1500 N (by 100 N steps). Conforming to Hamburg type AASHTO T324 and EN 12697-22 Small Size Device, in-air and in-water conditioning. Complete with both stainless steel and rubber wheels, laptop PC, software and clear transparent sliding doors. Set of moulds to be ordered separately. 380 V, 50 Hz, 3 ph+N Main features:

This universal version complies either to AASHTO or EN standards being equipped with both stainless steel and rubber wheels, and performing the test in air or water. This solution is particularly suitable for research laboratories. This version can be upgraded with automatic system which lift one of the wheel from the specimen that has reached the rut target continuing the test on the other specimen. The Double Wheel Tracker can be used as part of your Superpave performance based testing program. |