Uniaxial & Triaxial Accessories

ASTM D5407 | ASTM D7012 | ASTM D3967 | ISRM

|

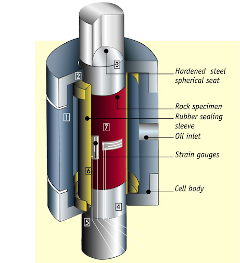

Hoek triaxial cells are offered in five models of different size; each one consists of the following:

The strain gauge measurements can be performed by automatic or semi automatic testing systems. The cell pressure and saturation pressure for permeability tests are carried out by the use of appropriate equipment. 32-D0553: Hoek cell, AX, for specimen dia. 30.10x60 mm, total height 213 mm 32-D0554: Hoek cell, 1.5 in., for specimen dia. 38.10x75 mm, total height 264 mm 32-D0555: Hoek cell, BX, for specimen dia. 42.04x85 mm, total height 263 mm 32-D0556: Hoek cell, NX, for specimen dia. 54.74x100 mm, total height 304 mm 32-D0557: Hoek cell, HQ, for specimen dia. 63.50x127 mm , total height 310 mm Accessories for compression test 32-D0556/A: Pair of load spreader for uniform load distribution 32-D0556/B: Distance pad to reduce the vertical clearance of the compression machine 32-D0556/H: Hoek cell holder compatible with Hoek cell codes 32-D0553, 32-D0554, 32-D0555 and 32-D0556. Not required for Hoek cell HQ type code 32-D0557 It is also recommended the use of a Specimen extruder to extrude the rock sample from its jacket thus avoiding to empty the confining fluid. 32-D0577/B: Specimen extruder for Hoek cells series 32-D055x, requires adaptors 32-D0577/1: Extruder adapter set for specimen AX, for cell 32-D0553 32-D0577/2: Extruder adaptor set for specimen 1,5 inch, for cell 32-D0554 32-D0577/3: Extruder adaptor set for specimen BX, for cell 32-D0555 32-D0577/4: Extruder adaptor set for specimen NX, for cell 32-D0556 32-D0577/5: Extruder adaptor set for specimen size HQ, for cell 32-D0557 |

|

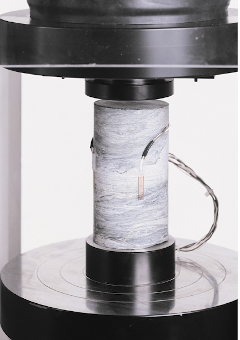

Strain gauges for uniaxial and triaxial tests provide a very accurate electrical signal, strictly proportional to the strain of the specimen submitted to load application, for determining the Elastic Modulus and strength characteristics as alternative to the Compressometer-Extensometers.

82-P0390: Strain gauge, 9.53 mm gauge length. Pack of 5 82-P0391: Strain gauge, 20 mm gauge length. Pack of 10 82-P0392: Strain gauge, 30 mm gauge length. Pack of 10 82-P0393: Strain gauge, 60 mm gauge length. Pack of 10 82-P0399/1: Connecting terminals, 50 pairs sheet They can be applied to the specimen surface by a special Adhesive-Catalyst agent and other accessories all included in the Strain gauge application kit. 82-P0399/C: Strain gauge application kit including: conditioner, neutralizer, acetone, tweezer, adhesive with catalyst agent, 100 m of bipolar cable, solder, soldering iron, scalpels, scissors, duct tape, sellotape, sandpaper and carrying case. 82-P0398: Compensation device for up to 4 Wheatsone bridges with ¼ or ½ bridge setup 82-P0399/P22: Adhesive and catalyst agent to glue the strain gauge to the specimen Up to 4 strain gauges ¼ bridge, and up to 8 ½ bridge, can be directly connected by one or two interfaces 82-P0398 to MCC8 and ADVANTEST 9 Control consoles which are suitable for cyclic loading and automatic determination of the Modulus of Elasticity. Strain gauges can also be connected, by one or two interfaces 82-P0398, to a suitable data logger as, for example, the Datalog 8, 82-P9008. |

|

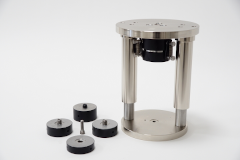

We propose two compression device models for indirect tensile test (splitting test) conforming to ASTM D3967 and to ISRM Specifications.

32-D9032/H: Compression device for indirect tensile tests on rock specimens conforming to ASTM D3967. Supplied complete with distance piece for specimen dia. 54 mm This apparatus, originally developed for testing in compression cement specimens, can also be used for splitting tensile test on rock disks with dimensions from dia 54 mm to 64 mm. 32-D9032/NX: Compression device for indirect tensile test on rock specimens NX type (dia. 54.74 mm) consisting of two steel loading jaws, guiding pins and half ball bearing. Conforming to ISRM specifications. 32-D9032/HQ: Compression device for indirect tensile test on rock specimens HQ type (dia. 63.5 mm) consisting of two steel loading jaws, guiding pins and half ball bearing. Conforming to ISRM specifications. All models above can be used as accessories with a suitable universal tester. This compression jig is strictly compliant to ASTM D7012 Rock core specimens Test Methods, in particular the spherical seat / compression plates / specimen diameters’ ratios fall within the prescriptions. 32-D9035: Compression device for rock core specimens with dia. from 54.7 mm (NX) to 63.5 mm (HQ) conforming to ASTM D7012: - upper spherical seat and compression platens dia. 80 mm with hardness 58 HRC - loading head stroke: 66 mm - vertical clearance: 167 mm - overall height: 333 mm. - supplied with distance pieces to reduce the vertical clearance: 2x h 30 and 1x h 22 mm - max. loading capacity: 1,200 kN It consists of a heavy duty twin-column frame, a spherically seated upper platen hold by calibrated springs and a lower platen centred on the frame base. The high stiffness structure and the high performance steel of the spherical seat make this device particularly suitable for high strength rock specimen featuring brittle properties and explosive failure. It shall be preferably fixed on the compression machine piston head by the threaded pin included in the supply compatible with all CONTROLS compression frames / machines. |