SMART-Line control consoles

EN 12390-4 | ASTM C39 | AASHTO T22 | NZS 3112.2:1986 | AS 1012.9:2014 | AS/NZS 4456:2003

|

WIZARD Auto is CONTROLS new standard automatic Quality Control system for compression and flexural testing and includes many new features and enhancements to improve the user-friendliness, efficiency, operator comfort and energy savings.

50-C10W02: WIZARD Auto SMART line, Automatic Control Console 230 V, 50-60 Hz, 1 ph WIZARD Auto is also available in a stand-alone configuration providing a cost-effective way to retrofit any make of compression testers fitted with old Bourdon gauges or unreliable electronic readout unit and power pumps with manual flow control. |

|

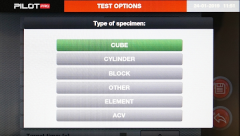

PILOT PRO is CONTROLS’ new versatile automatic Smart-Line control consoles for standard failure tests. It is the best choice for Quality Control laboratories to carry out a high throughput of routine failure tests including compression, flexure and indirect tensile tests.

Designed to fit all CONTROLS models of compression and flexural frames ranging from 100 to 5000 kN, it's been further upgraded using the latest technologies thus maintaining a very competitive price. The automatic compression testers with the PILOT PRO System have been the most reliable, economic and advanced solution for the standard concrete testing laboratories. Recommended bundle: 50-C10P02: PILOT SMART line, Automatic control console, for connection of one testing frame. 230 V, 50-60 Hz, 1 ph 50-Q60P/PR: Upgrade of a PILOT PRO system to incorporate a serial graphic printer, allowing results (including a load/time plot) to be printed at the end of test. 50-SW/DM: Datamanager PC Software suitable for data acquisition, processing and filing. Allows printout of customized test certificates. LAN cable included. PILOT PRO Smart-Line control console requires a suitable pressure transducer and connecting cable in order to operate a testing frame. Factory upgrade for a second frame connection and control (not simultaneously) available on request. LinkLAB is CONTROLS’ new proprietary Laboratory Connectivity Package. It allows your PILOT PRO to be a connected part of your laboratory infrastructure by taking inputs from any number of ancillary measuring systems and devices increasing efficiency and eliminating transposing errors. |

|

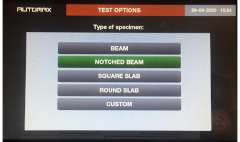

AUTOMAX PRO is CONTROLS’ new top-of-the-range Smart-Line control consoles and is the first choice for automatic standard failure tests and advanced concrete mechanical properties assessment. A major development are the new cutting-edge connective technologies. Three packages are available:

Recommended bundle: 50-C10F02: AUTOMAX PRO SMART line, Automatic control console, for connection to two testing frames. PC not included. 230 V, 50-60 Hz, 1 ph 50-Q60P/PR: Upgrade of AUTOMAX PRO system to incorporate a serial graphic printer, allowing results (including a load/time plot) to be printed at the end of test. 50-SW/DM: Datamanager PC Software suitable for remote control of automatic compression machine (AUTOMAX only), data acquisition, processing and filing. Allows printout of customized test certificates. LAN cable included. AUTOMAX PRO Smart-Line control console requires a suitable pressure transducer and connecting cable in order to operate a testing frame. Factory upgrade for a third and fourth frame connection and control (not simultaneously) available on request. AUTOMAX PRO-M Power Control System fitted with superior hydraulics can also perform, in addition to standard failure tests, the Modulus of Elasticity Determination tests and Characterizations of Fiber Reinforced Concrete (FRC) under displacement-control. 50-C10F02/M: AUTOMAX PRO-M SMART line, Automatic control console, for connection to two testing frames. PC not included. 230 V, 50-60 Hz, 1 ph |

|

Wizard Auto Power and Control System can be cost-effectively used to retrofit and update old testers to be transformed in a modern automatic compression tester. Both hydraulic system and digital interface have to be fitted laterally to the testing frame (lateral wall-mounting bracket included).

50-Q90W02: Wizard Auto Automatic Power and Control System 230 V, 50-60 Hz, 1 ph The hydraulic system consists essentially in a dual stage pump and AC motor fitted with inverter device featuring high efficiency, reduction of power consumption and silent operation. The digital interface features two 16 bit analog channels for load sensors, wide graphic display 128 x 80 pixel for real time view of load and stress and automatic application of the selected load rate. PILOT Pro and AUTOMAX Pro automatic and super automatic Power and Control Systems are also available in a stand-alone configuration that can be cost-effectively used to update any make of testers fitted with old pressure gauges or less reliable electronic readout unit and power pumps with manual flow control. |